1989 Wanderlodge Wide Body Pusher (WB)

| |

| Year | 1989 |

|---|---|

| Type | Wanderlodge Wide Body Pusher |

| Engine | Detroit Diesel 8v92TA-475hp with DDEC |

| Suspension | Ridewell RAD-227WB Air Suspension |

| Generator | Kohler 12.5kW Diesel |

| Tires | Michelin 12R22.5 |

| Transmission | Allison MTB 748 4-Speed with Retarder |

| Breaks | Full Air |

| Bathrooms | Walk Thru Side Bath |

| HVAC | |

| A/C | 13,500 BTU - 3 Rooftop 18,00 BTU - 1 Automotive (Dash) |

| Heating | |

| Tankage | |

| Diesel Fuel | 300 gal. |

| Fresh Water | 116 gal. |

| Gray Water | 105 gal. |

| Waste Water | 105 gal. |

| Propane (LP) | 45 gal. |

| Dimensions | |

| GVWR: | 40,000 lbs |

| Length: | 40' |

| Width: | 102" |

Overview

Operation

This section provides information on the operation and function of the controls, indicators and gauges located in the pilot/co-pilot compartment that are used in connection with the coach automotive systems. Figure 2-1 illustrates the pilot/co-pilot compartment, high-lighting the instrumentation and panels covered in this section.

Instrumentation

All essential operating controls and gauges used to monitor and control associated engine, generator and coach systems are located conveniently on and adjacent to the electroluminescent dash panels, figure 2-2.

Associated instrumentation, accessible on the bulkhead above the pilot, includes generator ON OFF switch, altimeter and diesel fuel filter monitors. Refer to figures 2-2 through 2-13 and the following paragraphs for locations and functions of associated operating controls and indicators.

Pilot Control Center (Dashboard)

You are now seated in the control center of your new coach. You have control of all engine functions , generator functions as well as all accessory functions at your fingertips.

Our new dash layouts for 1988 were designed for viewing continuity as well as function and beauty. You will notice as you drive that viewing angle changes only slightly from the road to any part of the dash.

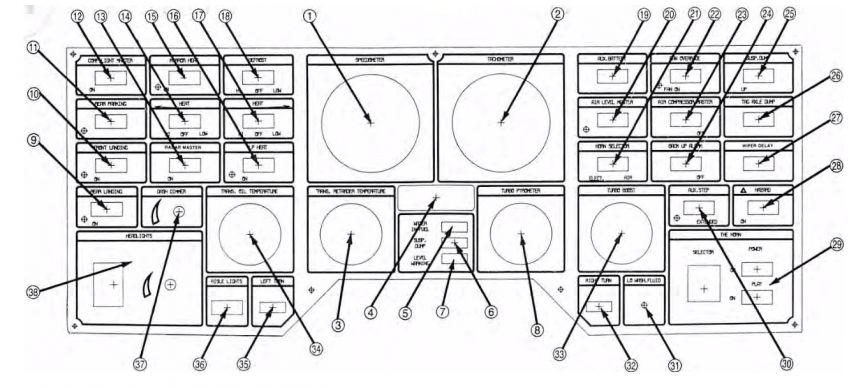

The dash is divided into eight main panels, (fig. 2-2) which are the upper dash panel, lower dash panel, shifter panel, upper right hand dash panel, lower right hand dash panel, monitor panel, monitor control panel and inverter panel. The gauges, switches and warning lights installed in these panels will be explained as far as function and operation in the following text.

NOTE: Some items operate at all times, some require the 12 volt master to be on, while others need the 12 volt master and the ignition on. Gauges marked with an * require the engine to be at normal operating temperature for correct readings.

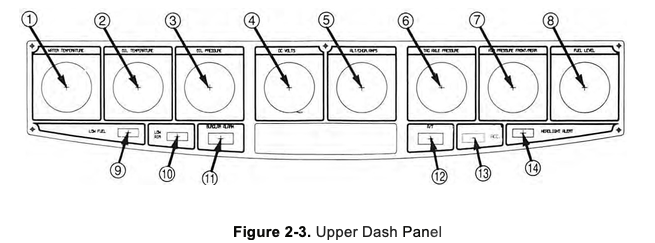

Upper Dash Panel

- Engine Water Temperature - Normal water temperature should be between 180° and 210° for safe operation.

- CAUTION: If the Engine Temperature gauge indicates excessively high temperatures, the engine may be over-heating and should be stopped to prevent damage. Allow the engine to cool before check ing the radiator coolant level.

- Engine Oil Temperature - Gauge-Gives a constant reading of the engine oil in the supply line from the pump. The normal operating temperature is from 200°F to 250°F. If the temperature goes over 250° the engine may be low on oil or there is overheating of the cooling system.

- CAUTION: Your Wanderlodge is designed to operate at ambient temperatures up to 100°F with no problems. If temperatures greater than 100°F are encountered, the operator must closely observe engine water and oil temperature and trans mission oil temperature to avoid over heating conditions. If overheating conditions occur at ambient temperatures less than 100°F, the cooling system must be checked and problem corrected.

- Engine Oil Pressure - Indicates the pressure of the oil, not the amount of oil in the engine reservoir. This gauge will normally read be tween 50 and 70 psi during cruising speeds; and drop to a minimum of 5 psi when the engine is idling.

- CAUTION: No oil pressure, or low oil pressure readings (below 25 psi) when engine is operating at cruising speeds are trouble indications! Do Not Operate the Engine Under These Conditions!

- DC Volts - Registers the actual voltage at the coach batteries. With the engine running, gauge should read14 volts (+ or - 0.5).

- Alternator Charging Amps - Shows total charging current in amperes. With the engine run ning, total alternator output is shown. When parked, with a source of 120 volt ac, (outside power or generator), the gauge will show total output of the battery chargers.

- Tax Axel Pressure - The tag axle suspension pressure is factory set at 60 psi on WB-38 & 40 coaches

- CAUTION: Before driving check gauge to make sure there is pressure in the tag axle air bags. This is critical for proper coach axle weight distribution.

- Air Pressure Front/Rear - The Dual Air service Brake Pressure systems are engine operated and supply independent brake system air pressure for front and rear service brakes and the parking brake. During normal operation, each air pressure gauge reading will build up to 100 psi to 120 psi shortly after the engine is started. Note that, as a safety feature, the parking brake cannot be released until air pressure readings are at least 65 psi.

- Fuel Level - Indicates the amount of diesel fuel remaining in the 300 gallon fuel tank. Note that the 12.5 kw generator also gets its fuel supply from the 300 gallon tank. This gauge reads only when the ignition switch is in ON or ACCESSORY position. As a precaution against generator operation draining the fuel supply, the generator fuel pickup is shorter than the engine pickup. Separate fuel filters are provided for each fuel line.

- Low Fuel Light - When this light comes on it is an indication that the operator should be looking for the nearest refueling station.

- Low Air Warning Indicator - This light is associated with a buzzer. These warn the driver that there is an insufficient supply of air (65 psi or less) to properly operate the coach. If the air pressure is low, when the ignition key is turned on, the light and buzzer will come on immediately. Both warnings will continue until the air pressure is built back up, or the ignition key is turned off.

- Burglar Alarm Switch - There are two switches that turn the Burglar Alarm on and off. The switch on the dash is used when you are inside the coach. The weather proof key switch, outside the coach next to the entrance door , is used when you are going to be leaving your coach for awhile. Note that both switches operate independently of one another. If the Burglar Alarm is turned on at the dash, then it must be turned off at the dash. The outside switch works on the same principle.

- A/T (Anti-Theft) - deactivates the starting system for protection against unauthorized cranking and theft.

- Accessory - These BLANK positions may be used for the installation of additional switches and indicator lights for customer add on equipment.

- CAUTION: Use existing panel holes for installation of additional controls or indicators. Drilling new holes will destroy the electroluminescent features.

- Headlight Alert - When the ignition switch is turned off and the headlight switch is on, this red warning light, along with a buzzer , will come on. These will remain on until the headlight switch is turned off or the ignition switch is turned back on.

Lower Dash Panel

- Speedometer - Indicates speed and ac cumulated mileage (odometer). This is a solid state electronic monitor, with an RPM sensor located at the right drive axle brake drum

- Tachometer / Hour Meter - Indicates actual engine RPM (Revolutions Per Minute) when scale (0-25) reading is multiplied by 100. Idle RPM should be 600 and full load (uphill) 2100 RPM. HOUR METER shows number of hours engine has been in operation.

- Transmission Retarder Temperature - Measures temperature of the transmission retarder oil. If the gauge registers a temperature over the 330°F maximum safety range, reduce use of transmission retarder. See information on use of transmission retarder later in this section.

- High Beam - The Blue Bird logo is illuminated when high beams are selected using steering column switch.

- Water in Fuel - This light comes on when there is an excess of water in the bottom of the fuel tank

- Suspension Dump - Light flashes to tell you that the suspension system has little or no air, and that the suspension needs to be pressurized before the coach is driven.

- Level Warning - This light comes on when any of the four (4) leveling jacks is not fully retracted.

- Turbo Pyrometer - Registers the temperature of the exhaust gas output of the Turbo. The correct temperature of the exhaust should be around 740°F at maximum power.

- Rear Landing Light Switch - At the ON position this switch turns ON the landing lights in the front right and left panels just behind the front tires. These lights shine toward the rear of the coach so are called Rear Landing Lights. Note that a small blue indicator lights when the switch is ON.

- Front Landing Light Switch - To turn on the front Landing lights, located in the rear side panels just in front of the rear wheels, push this switch to the ON position. The indicator next to the switch should be lit when the switch is on.

- Rear Parking Light Switch -This switch controls the on-off operation of the rear parking lights (rectangular halogen lights above the rear bumper) when transmission selector lever is in R An indicator next to the switch lights when the rear parking lights are on.

- Comp. Light Master - When this switch in the ON position provides power to all of the exterior compartment light switches. As each compartment door is opened, the light automatically comes on; closing the door turns the light off.

- Radar Master - Turns on power to the Radar

- Heat - To turn on the heater blower for the pilot's area press this switch to either the HI- or LOW position. Note: when the front heat control is in cool position the heat switches (14) and (17) can be used to provide cool air circulation by turning on the blowers.

- Mirror Heat - This switch turns on a thermostatically controlled heater in the right and left outside mirrors (convex mirrors excluded ). With the switch ON the Mirror Heaters will automatically come on to defog the mirrors.

- LP Heat - When in the ON position, 12v. power is supplied to the LPG furnaces.

- Heat - To turn on the heater blower for the co-pilot's area press this switch to either the HI- or LOW position. Note that when the front heat control is in cool position the heat switches (14) and (17) can be used to provide cool air circulation by turning on the blowers.

- Defrost - Turns on the blower for defrosting or defogging the front windshield. Set to HI-or LOW speed as desired.

- Aux Battery - When this switch is pressed, a jumper solenoid connects the generator and coach batteries together (in parallel) to provide extra power for cranking the generator or coach. Releasing the switch immediately isolates the two battery systems.

- Air Level Master - Allows you to level the coach to a certain extent using the air suspension. This is an optional system and should only be used for short periods of time.

- Horn Selector - Allows selection of the air or electric horns when the steering wheel horn button is depressed.

- Fan Override - This switch operates the engine cooling fan in the engine compartment. Normally, this fan will operate at 125 to 400 RPM from an engine RPM of idle to 2100. If the coolant temperature reaches 195°F, the fan will be thermostatically controlled to run at 1800 RPM. To override the thermostat turn the Fan Override switch ON, and the engine cooling fan will turn 1800 RPM continuously at any temperature.

- Air Compressor Master - This switch operates the auxiliary air compressor (optional equipment) which is a 120 vac operated back up air compressor.

- Backup Alarm - This switch turns the back-up alarm buzzer off.

- Suspension Dump - This switch controls the inflation of the air suspension systems for the front and rear axles. Move switch to the right to dump the bags.

- Tax Axel Dump - In UP position tag axle air suspension is pressurized as indicated on dash gauge TAG AXLE PRESSURE . When switch is moved right pressure in tag axle is dumped.

- Note: SUSP. DUMP accessory warning light is lit: set switch to UP position to re-inflate the air bags before driving away. (System air pressure must be at least 65 psi.)

- Your motorhome is equipped with air suspension bags which cushion the front, rear and tag axles. Dumping these air bags when the vehicle is parked allows the rubber bumpers to come together and eliminate vehicle springiness. Two switches control dumping and filling of the respective air bags. The SUSP. DUMP switch controls the front and rear axle suspension; the TAG DUMP switch controls the tag axle only. Note: The accessory air tank must contain at least 65 PSI pressure for the air switch to function. The accessory air tank pressure does not register on the dash air pressure gauges.

- Moving the SUSP. DUMP switch to the UP position applies air pressure to three air pilot-operated valves on the suspension system. Two of these valves are located on the rear axle; and one is located on the front axle. The pilot air shifts the valves, cutting off the air supply to the air bags and allows the air in the bags to escape. After the suspension system has been dumped, and the ignition is turned on, a warning pilot light is illuminated on the dash to warn the driver that the system is dumped and not to drive the vehicle until the SUSP. DUMP switch is set to the up position. Note: If the leveling jacks are to be used while the coach is parked, the jacks must be lowered to level the vehicle before the air bags are dumped. If the air bags are dumped before the jacks are down, the vehicle is too low for the jacks to unfold into lifting position properly. This could damage the jacks. When dumping, the tag axle is dumped first, then the front and rear axles. However, when pressurizing, the front and rear axles are pressurized first, then the tag axle.

- Wiper Delay - Knob adjusts wiper speed from 2 to 20 sweeps per minute when intermittent operation is selected at steering column switch lever.

- Hazard Switch - This switch turns on the emergency flashers. When switch is used both turn signals will flash in unison.

- The Horn (Figure 2-4) - This corner of the dash has 3 different switches for use with the musical horn

- The SELECTOR switch incorporates 2 thumb wheels for selecting the tune to be played. Use The Horn manual to select a tune. Then set the thumb-wheels to the corresponding numbers or number and letter. Note: that if a tune is playing, making a new selection on the selector switch will not affect the tune playing.

- The POWER switch provides power to the musical horn. When this switch is turned ON the horn will immediately start playing the tune that corresponds to the digits on the selector switch.

- The PLAY switch (momentary) resets the horn to the beginning of tune chosen by the Selector switch. If the PLAY switch is pressed while a tune is playing, that tune will stop instantly and the horn will reset to the beginning of the tune that corresponds to the digits on the SELECTOR.

- Auxiliary Switch - When set to the EXTENDED position, activates a relay automatically locking the outside entry step in the out position. The indicator light comes on when the ignition switch is turned on to remind you that you need to retract the step before proceeding.

- Low Washer Fluid Light - Light indicates when there is approximately 1 /4 contained in the fluid reservoir.

- Right Turn Indicator - When the turn signal lever , (steering column control section), is pushed up into the right turn position this indicator flashes in conjunction with the outside directional lights . The right cornering light will come on continuously if the headlights or the parking lights are turned on while the turn signal lever calls for a right turn. The indicator , along with the left turn indicator and all outside directional lights, flash in unison when the HAZARD switch (item 28) is pressed to the on position .

- Turbo Boost Gauge - Registers the psi of the Turbo Compressor outlet. The gauge should read a maximum of 23.2 psi at maximum power.

- Transmission Oil Temperature Gauge - Monitors and gives constant temperature readings of the transmission oil. Maximum allowable is 330°F.

- Left Turn Indicator-When the turn signal lever is pulled down into the left turn position , this indicator flashes in conjunction with the outside directional lights. The left cornering light will come on continuously if the headlights or the parking lights are turned on while the turn signal lever calls for a left turn.

- Aisle Lights - This switch allows you to turn on or off the fluorescent aisle lights from the pilot 's chair.

- Dash Dimmer - Will only operate when the headlight switch is on. The background lighting (electroluminescent) for the dash can be brightened by turning counter-clockwise and dimmed by turning clockwise.

- Headlights - The Headlight switch serves two functions . Press P for parking lights and gauge illumination. Press the bulb symbol for headlights, parking lights and gauge illumination. The dimmer controls brightness of all gauges in dash. Turn counter-clockwise to increase or clockwise to decrease the brightness .

Shifter Panel

- Transmission Shift Selector - Figure 2-5 shows the selector for the 8V92 engine. This is the push button shift selector made avail able with the Allison Transmission Electronic Control (ATE C). With ATEC, shifts are more accurate and positive than those obtainable with conventional hydraulic controls. ATEC makes it possible to precisely match the optimum fuel economy/shift curve relationship. Only four speeds are required with this system. See Diesel Engine/Transmission Operation later in this section for detailed description.

- Transmission Retarder - Provides power to Transmission Retarder/Brake System. The adjacent indicator lights when the retarder is operational. Use of RETARDER HAND CONTROL will be covered later in this chapter.

- Accessory Position - These blank positions may be used for the installation of additional switches and indicator lights for customer add on equipment.

- Caution: Use existing panel holes for installation of additional controls or indicators. Drilling new holes will destroy the electroluminescent features.

- Marker Lights - Press this switch to ON to turn on the clearance, side marker and identification lamps located on the top sides and ends of the coach. This switch may also be flipped on and off to flash the marker lights as a courtesy signal.

- Driving Lights - The driving lights are mounted behind the front bumper in a retracted position. When the switch is energized the driving lights are lowered into position (if the suspension is at ride height). The driving lights do not come on unless the high beam light switch is energized and the driving lights are in the down position. The driving lights go out when the lights are switched to low beam or when the driving lights switch is turned off. When the driving lights switch is turned off the driving lights retract back to the stored position.

- Cruise Control - These three switches operate in the following manner: The switch on the left turns the cruise control on or off. The switch on the right locks the cruise control in on the desired cruising speed and permits resetting at a lower speed following a previous setting. The switch in the middle permits returning to cruising speed following disengagement by stopping and obtaining a higher cruising speed.

- Note: The coach must be traveling at least 35 MPH before the cruise control will operate properly. When the desired speed is reached, press the On-Off switch to the On position, then press the Set-Coast switch to the Set position and hold for two seconds before releasing. The coach should automatically remain at that speed. If a lower cruise speed is desired, press the Set-Coast switch to the Coast position and hold until the de sired cruising speed is obtained. Release the switch immediately. The coach should remain at the new speed. Following disengagement of the cruise control by breaking the previously set cruising speed may be obtained by depressing the Resume-Accel switch to the Resume position for two seconds. Note that the coach should be at or above 35 MPH before attempting the Resume function. In addition, if the ignition switch has been turned off, the previous cruise speed will be erased from memory and the new cruise speed will be that speed when the Resume switch was pressed. If a higher cruising speed is desired and the cruise is enabled, press the Resume-Acee! switch to the Accel position. The coach will begin to accelerate. When the higher desired cruising speed is obtained, immediately release the Accel switch. The coach should remain at the new speed.

- Engine Monitor Switches High Idle - This switch when turned to On, in creases the engine idle speed to approximately 1100 RPM. This will provide a faster engine warm up and also provide better cooling when stopped in traffic with chassis AIC on.

- Engine Stop Override - This switch momentarily overrides DDEC engine shutoff system.

- Stop Engine Light - Indicates when a potential engine damaging condition has been detected .

- Check Engine Light - Indicates that a problem has occurred.

- Engine Test - This switch is to check the system for problems.

- Transmission Check Light and TEST SWITCH - ATEC has a built-in diagnostic system . If any problem should develop the Check Trans. light will come on. A Detroit Diesel Allison service facility will immediately be able to determine the cause by pushing the momentary Trans. Test rocker switch. The Check Trans. light will then blink out the code for the problem.

- Cockpit Light - This switch controls On-Off ope ration of the fluorescent lights.

- AC/Heat Master - These switches allow the driver to control roof air conditioners or the electric heaters.

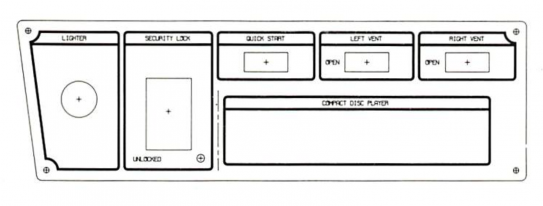

Upper Right Hand Dash Panel

- Lighter - Depress to heat the element; pops out when hot.

- Security Lock - Dual switches used to lock and unlock the deadbolt lock on the entrance door. A switch is also located on bed room control panel.

- Cold Start - When switch is pressed to on it sends a timed pulse of ether into the air intake of engine to help starting in cold weather.

- Left Vent and Right Vent - Operate the air cylinder controlled air vents to direct fresh air to the pilot and co-pi lot areas.

- Compact Disk Player - Space available for optional disc player with premium sound

Lower Right Hand Dash Panel

Ignition Switch - A four-position, standard type key switch . In OFF position (center), ignition and accessory positions are disabled and the key can be inserted or removed. In ON position (right) the battery is connected to the engine- run ignition circuits and the key can be advanced to START to start the engine, providing that the transmission selector is in neutral N position and toggle switch in engine compartment is up (front) . ACCESSORY position (left) allows operation of accessories without activating the engine-run circuits.

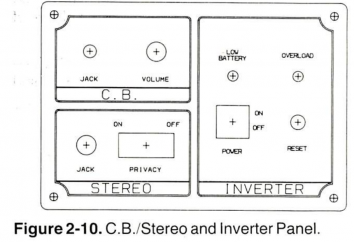

Wandersound Stereo - is comprised of the BLAUPUNKT LEXINGTON Tuner/Cassette with four (4) 6 x 9 inch coaxial pyle driver speakers and two (2) 6 ½ inch coaxial pyle driver speakers. The BLAUPUNKT Tuner/Cassette has auto reverse, electronic tuning sensor , Dolby noise reduction and metal tape capabilities. The speakers are located four (4) in the living room and two (2) in the bedroom. A privacy switch is located on the overhead panel above the driver's head. The privacy switch turns the living room speakers off. Headphone jacks are located on the hood table and in the bedroom. There is a volume control in the bedroom controlling the volume of the bedroom speakers.

Monitor Controls - Brightness contrast and On/Off controls adjust in the same manner as any black and white TV.

Front Heat Control -This slide control opens or closes the valve in the front heater hose line for heating or cooling.

C.B. - Jack for headphone listening with volume control.

Stereo - Stereo jack for headphone use with AM/FM Stereo Tuner/Cassette player and optional disk ·player. Privacy switch when turned on cuts power to all front speaker. Use switch when stereo headphones are used.

Inverter - Space for optional inverter controls. (See Inverter section for information)

Overhead Control Center

- HEAT SELECTOR - Operates solenoid valves in engine coolant line to divert coolant flow through hot water heater and chassis heaters when this switch is in WINTER position. Setting the switch to SUMMER position causes the coolant to flow through the hot water supply heater coil only .

- AUX. PUMP - Controls the auxiliary water pump (under floor at road side rear) that boosts the circulation of engine coolant through the water heater heat exchanger and chassis heaters in the bedroom , bathroom , dinette and living room.

- DASH DIMMER - This control will only operate when the headlight switch is on. The background lighting (electroluminescent) for the upper dash can be brightened by turning counterclockwise and dimmed by turning clockwise.

- SPOTLIGHT SELECTOR - Depressing switch , left or right, selects LH or RH light operation.

- SPOTLIGHT BEAM SELECTOR - Depressing left side of switch activates FLOOD while right side pressure selects SPOT . Center position is OFF.

- SPOTLIGHT SPEED - Adjusts speed of light head movement.

- SPOTLIGHT AIM - Controls horizontal and vertical beam position.

- CAMERA DEFOG - Energizes fan in compartment for Closed Circuit TV (CCTV) camera.

- AIR CONDITIONER LEFT FAN - Three speed blower for left front area of coach. Left fan switch must be in either HI, MED, or LOW to energize compressor.

- AIR CONDITIONER Temperature - Thermostat setting controls temperature by cycling compressor.

- AIR CONDITIONER RIGHT FAN - Three speed blower for right front area of coach.

- CLOCK PANEL - This panel includes a digital readout. Four switches to the left of the display set clock timing. To set TIME display set clock timing. to set TIME qispl~y, press HR SET/MIN SET switch to HR SET position and hold until correct hour is displayed; repeat with switch in MIN SET position until correct minutes are displayed. The ELAPSED TIME display will show elapsed time in terms of hours and minutes , or in minutes and seconds , depending on the position of the HRS/MIN - MIN/SEC switch. Set this switch a!'; desired, press ZERO to reset the display to 00:00 readout , and the elapsed time will count. The HOLD/GO switch may be set to HOLD position to suspend operation of the elapsed time display ; for elapsed time operation, leave switch in GO position.

- SAFELINE ALARM - The Safeline alarm operates whenever the shoreline is connected to the coach and the ignition switch is in ON position as a reminder to disconnect the shoreline before driving away. With the Safeline switch ON, the alarm is given by buzzer sound and red light. The buzzer can be deactivated in favor of a flashing amber light by turning off the switch.

- ACCESSORY - These Blank positions may be used for the installation of additional switches and indicator lights for customer add on equipment. Caution Use existing panel holes for installation of additional controls or indicators.

- WATER IN FILTER - Light and buzzer alarm.

- GENERATOR START/STOP - Provides local control for generator operation. Press this center-off momentary switch to ST ART position and hold until generator starts , as indicated by the switch indicator illuminating . If generator does not start within 2 to 5 seconds, release switch, wait 30 seconds, then try again. To shut down the generator, press to OFF position and hold until light extinguishes.

- TRIP ODOMETER-Depress bar to reset.

- ANTENNA - Both switches must be pushed simultaneously to cause raising or lowering of TV antenna. Indicator will light when TV antenna is up from its secured position when ignition switch is turned on.

- ALTIMETER- Indicates coach height above sea level. (Zeroing adjustment can be used to calibrate unit at known elevations.)

- FUEL VACUUM GAUGE - Racor fuel filter element should be changed when pointer goes into red.

Co-Pilot's Overhead Dash

GENERATOR OIL PRESSURE - Shows the oil pressure, not amount of oil in the generator engine reservoir. This gauge will normally read between 30 and 60 psi. Low oil pressure indications are often a symptom of possible generator failure. Oil level should be checked on a regular basis. Note that the generator has a low oil pressure shut-off switch which operates if the generator oil pressure falls below 15 psi.

GENERATOR WATER TEMP. - Displays generator engine coolant temperatures from 100 to 240 degrees. Normal operating temperatures vary from 175 to 190 degrees. If consistently high temperatures are indicated , shut down the generator , wait for the engine to cool, then check radiator coolant level. Note that the generator has a high-temperature shut-off switch which operates if the generator temperature reaches 225 degrees F.

GENERATOR VOLTS - Expanded-scale voltmeter , with scale graduations from 10 to 16 volts, shows the condition of the generator battery . Normally, the battery voltage varies from 12 to 13 volts; under starting load it may drop to about 10.5 volts and then rise to about 14.0 when the generator starts and begins charging the battery through the external isolator unit and battery chargers. Battery voltage readings less than 10.5 or more than 15 are usually a symptom of an electrical system failure or impending battery breakdown.

GENERATOR HOURS RUN - Indicates total hours of generator operation .

D.C. AMPERAGE - Ammeter on left (labeled CHARGE) shows net current flow to or from batteries. Needle movement from the center of the gauge indicates discharge to the left and charge to the right. When parked, following highway travel , it is normal to see a needle position to the left of center even when plugged into shore power (or running generator). This will gradually diminish and should eventually show some movement to the right with coach loads turned off. Ammeter on right (labelled DISCHARGE) shows current demand of 12 volt load. A.C. VOLTAGE - Voltmeter on left monitors LEG ONE while that on right monitors LEG TWO of 120 volt alternating current circuits.

A.C. AMPERAGE -Ammeters show current flow in LEG ONE (left) and LEG TWO (right) of 120 volt alternating current circuits. Polarity Normal indicator (green), lit whenever the shoreline hookup is properly connected and grounded and line polarity is compatible with coach wiring and a Polarity Reversed indicator (red) which lights when hookup is reversed. A faulty ground connection is indicated in none of the LEDs is lighted.

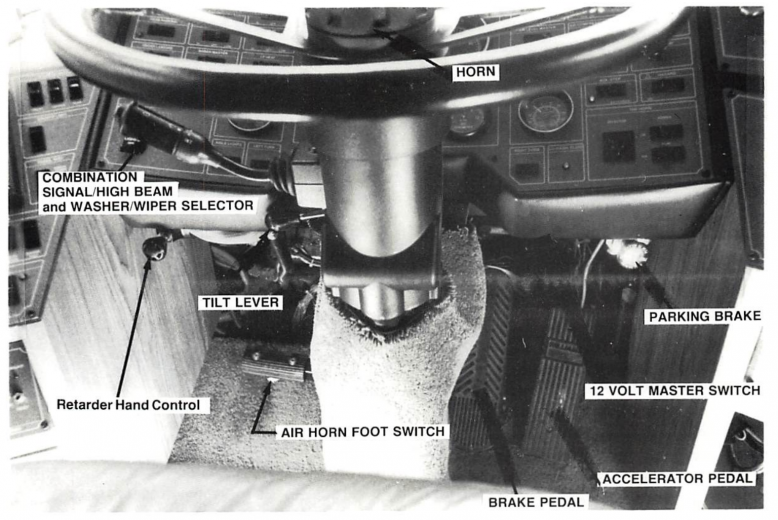

Steering Column Area

The steering column area, figure 2-14 includes controls located on the steering column, and under the dash .

HORN - Operate the horn by pressing in on the center section of the wheel. Select air or electric horn with the

HORN SELECTOR switch on the dash.

COMBINATION TURN SIGNAL/High BEAM and WASHER/WIPER SELECTOR - Push lever toward dash for right turn signal , pull lever away from dash for left turn signal. Pull lever up toward steering wheel and hold for momentary high beam. When lever is released low beams are activated . Push lever down until switch is activated for high beam operation. Pull lever back toward steering wheel to go to low beam operation. The washer ring is located at the end of the lever and when pushed activates the windshield washer , but only when the wipers are activated. To activate the wiper twist lever from "O" position to I or II for continuous speeds or to INT for intermittent operation. When in INT position_ the delay of the wipers can be changed by the wiper delay knob on the lower dash panel. Twist lever back to "O" position to turn wipers off.

TILT LEVER - Pull lever up to release lock mechanism . While holding lever up, adjust the steering whee l to a comfortable position and release lever. Move the steering wheel slightly to make sure the column locks into position.

TELESCOPING STEERING WHEEL - to unlock telescoping wheel twist center sect ion of steering wheel counter-clockwise and adjust wheel to comfortable position. While holding steering wheel at desired position with one hand lock it into position by turning the center section of wheel clockwise.

PARKING BRAKE - The Parking Brake control is located under the lower dash , to the right of the steering column. Note that the parking brake cann t be released unless the system air pressure is at least 65 psi.

12 VOLT MASTER SWITCH - This switch is hidden under the lower dash, to the right of the steering column. Use this switch to shut off the 12 volt battery power to all circuits except the digital clocks, radio memory, monitoring panel functions, refrigerator controls, and burglar alarm.

ENGINE SHUTOFF CONTROL - (Only on California model) This control is located under the lower dash just to the left of the steering column. In the event that turning the ignition switch to OFF does not shut down the engine , pull this control (PULL TO STOP) fully outward. This operates a positive mechanical linkage to shut off fuel to the engine.

Floor Controls

AIR HORN FOOT - Operates highway horns. Close to steering column.

ACCELERATOR PEDAL - Controls engine fuel flow to select power output. See Diesel Engine /Transmission Operation later in this sect ion for detailed description.

BRAKE PEDAL - The coach is equipped with a dual air brake system which includes independent systems for the front and rear service brakes. A separate reservoir and panel-mounted pressure gauge is provided for each service brake system. (Air Pressure Front and Rear).

Radar Detector A high-sensitivity superheterodyne microwave radar detector is installed as standard equipment on your coach . This unit, is designed to activate when transmissions are received from radar-type speed detection equipment. The radar master switch (on the lower dash panel) is used to supply power to the radar detector.

Controls and Indicators

Seat Controls - Electrically and air-operated six-way seat adjustments are built into the pilot's and co-pilot's seats. A typical control panel is shown in figure 2- 15. Three electric SEAT CONTROLS are used to control seat bench tilt, up-down and front-back seat movement , and seat back tilt. The SIDE SLIDE switch operates an air cylinder which locks the position of the slide mechanism beneath the seat. Press switch to disengage the seat slide lock, adjust side-to-side position, then release switch to re-engage lock mechanism. This switch must be kept LOCKED to secure the seat during travel. These seats may be rotated by releasing the lever underneath the seat base on the right side.

Closed Circuit TV Monitor System - System Components Besides the TV receiver on the lower dash , the CCTV Monitor receiver system also includes: • CCTV camera, located in the rear of the coach, figure2-16. • Picture brightness , contrast and ON/OFF switch on lower dash. CCTV Operation The rear-facing CCTV camera transmits images directly to the monitor via coach cabling. Note that the system requires a brief warmup period before achieving full resolution. CCTV camera controls are preset and the standard lens supplied with the unit is designed to focus from about two feet to infinity.

TV Antenna and Rotator System - The control components of the antenna and rotator are a hand-held switch-operated rotator, radome-type TV roof antenna , switcher for the antenna or cable inputs and a switch for raising and lowering the antenna. The A-B switch , switches antenna A or cable B input via connections in shoreline compartment at the rear of the coach to the TV receptacles via the VCR (if present). The antenna rotator controls the position of the TV antenna within the radome. The three-position momentary switch ( center OFF) provides right/left antenna rotation. The radome includes an amplifier and rotator mechanism. The remote power supply operates from 12 volts de. Low-loss coaxial cable and three wire rotator control cable interconnect the antenna and power supply.

Note that the system is protected by a fuse in the overhead load center. In the event that the TV set exhibits problems relating to low antenna input (ghosts,etc .) check this fuse before servicing the TV set.

Antenna Operation With the TV on and a station tuned in, rotate the antenna by pressing the rocker switch located on the control unit. Press the right side of the switch to turn the antenna clockwise; press the left side to turn the antenna counter-clockwise . Although the actual antenna movement is not visible, the indicator arrow on the control unit lights and shows the direction of movement. When the antenna has made one full turn (360 degrees) , the End of Rotation light comes on. Observe the picture while rotating the antenna, first in one direction , then the other , to obtain best picture quality . The switches for raising or lowering the antenna are located in the Pilot's Area Overhead Dash and Radio Panel, figure 2-12, item 18.

CB transceiver Unit has all the functions in the mike , while the electronic parts are in the black box module mounted in the dash area. Controls and Indicators - See CB Owners Manual.

Diesel Engine /Transmission Operation

Proper operation and maintenance are key factors in determining the useful life and operating economy of a diesel engine. Follow these directions for trouble-free, economical operation.

To Start Engine

Detroit Diesel Engines will start at temperatures above 0 degrees F ( - 12 degrees C) without using a starting aid. However, for colder temperatures it may be necessary to activate the engine block heater (120 volt ac-operated) to heat the crankcase oil. The ENGINE BLOCK HEATER is controlled by the battery heater breaker. Remember to set the breaker OFF when the heater is no longer needed.

- Place transmission in NEUTRAL.

- Turn ignition switch to START. Engine should start within 5 seconds. If engine fails to start within 30 seconds, release the starter switch and wait 60 seconds to allow the starter motor to cool before trying again.

- As soon as the engine starts, reduce engine speed to low idle. After normal oil pressure is indicated, HIGH IDLE may be used to build up air pressure more rapidly.

- Do not apply a load to the engine or increase engine speed until oil pressure gauge indicates normal.

- Operate the engine at low load until all systems reach operating temperatures . Check all gauges during warmup period.

Remote Engine Starting

Because it may sometimes be necessary to start the diesel engine remotely, a separate key switch is located on the right side of the engine compartment. This ignition switch has no accessory position; only OFF-ON and START positions can be used. Be sure the hinged switch cover is snapped back in place after key withdrawal to prevent moisture damage. Toggle switch must be down (REAR) to start from engine compartment.

To Stop Engine

Caution Before stopping the engine, operate at low idle for a minute or so. This will allow hot areas in the engine to cool ·gradually and extend engine life.

With the vehicle stopped, apply the parking brake and place the transmission shift lever in NEUTRAL. Turn the ignition switch to the OFF position. This shuts off the fuel supply to the engine.

Using the Allison Transmission Brake /Retarder

Your Wanderlodge is equipped with a transmission brake/retarder for your safety and driving convenience. The retarder system is energized by an OFF/ON switch on the shifter panel (see figure 2-5). There are two methods of activating the system (putting it to work):

- Depressing the brake treadle

- Downward movement of Retarder Hand control

Either of the above actions will result in transmission retarder braking action and illuminate the blue indicator light at the dash OFF/ON switch.

Retarder braking effort is proportional to hand control or brake treadle movement. The cruise control will automatically disengage when the retarder is activated. If after braking, you would like to pick up your original cruising speed, press the RESUME-ACELL switch to the RESUME position for two seconds.

When operating the retarder observe transmission retarder and engine temperature at all times. If transmission retarder temperature exceeds 330°F reduce vehicle speed and manually select a lower gear.

On extremely long down grades, water (coolant) temperature could exceed recommended limit (220°F.). Under these circumstances, reduce vehicle road speed with service brakes and downshift to increase engine RPM.

The function of the retarder is to provide auxiliary braking in all conditions by combining both hydraulic and clutch pack retardation capabilities. The retarder is installed on the rear of the transmission in place of the output housing. In most applications the output retarder is applied in conjunction with the service brakes. Selecting a lower hold range position when using this type retarder is recommended for maximum effect.

Cautions: Apply and operate the retarder with engine at closed throttle only. Do Not use the retarder when road surfaces are slippery. Do not apply retarder control or de-energize the system at the master control switch. Observe transmission and engine temperature limits at· all times. Select the lowest possible transmission range to increase the cooling system capacity and total retardation available. In the event of overheating, decrease vehicle speed to reduce retardation power requirements . Observe the retarder "ALERT LIGHT" to ensure that the vehicle control system is functioning properly.

Trailer Hitch

Hitch capacity is 10,000 pounds tow and 1,000 pounds tongue weight. Note Trailer hitch ball capacity is 6,000 pounds. Nut must be torqued to 200 ft.- lb. Towing Two towing eyes are provided behind the upper part of the generator door. Remove the two door side covers (panels) for access.

Caution Do not tow a vehicle equipped with Allison automatic transmission unless the drive shaft has been removed, or the rear wheels raised from the ground. Do not attempt to tow unit by front axle or cross-member. Damage to wiring and/ or air lines can result because of proximity of these items to front crossmember/ Do not tow with generator tray extended. Do not tow by the bumpers. Air pressure is required to release brakes.

Transmission Operation

The Detroit Diesel Allison transmission (8V92 engine) provides four forward ranges and one in reverse. Speed selection is provided through the transmission shift panel. The selector must be in N (neutral) position when the engine is started . If the engine can start in any other position , the neutral start switch deficiency should be corrected as soon as possible. Use D position for all normal driving conditions so that the coach begins moving in first gear and upshifts automatically into 2nd, 3rd , and 4th gears. As the coach slows , the transmission automatically downshifts to the correct gear. Use a low gear 2 or 3 when road, load or traffic conditions make it desirable to restrict automatic shifting to a lower range; or use the Allison transmission retarder , as .J previously described . Use 1 or 2 when pulling through mud and snow or driving up steep grades (See table 8-3 for gradeability) . The vehicle should be completely stopped before shifting into reverse.

Driving Tips

Accelerator Control

Foot pressure on the accelerator pedal influences the automatic upshifting or downshifting within each driving range . When the pedal is fully depressed against the floor pedal stop , the transmission automatically upshifts near the recommended governed speed of the engine . A partially depressed position of the pedal causes the upshifts to occur sooner at a lower engine speed. This throttle-modulation method provides the accurate shift spacing and control necessary for maximum performance.

Downshift Control

The transmission can be downshifted or upshifted , even at full throttle, and, although there is no speed limitation on upshifting , there is a limitation on downshifting and reverse . Good driving practices indicate that downshifting should be avoided when the vehicle is over the maximum speed attainable in the next lower gear . Allison transmissions incorporate downshift inhibitors to prevent harmful shifts when the vehicle is traveling too fast for the next lower gear. If downshifts are attempted at excessive speeds , the inhibitors prevent the selected downshift until the vehicle reaches an acceptable speed.

Transmission Oil Temperature

Extended operation at low vehicle speeds, with the engine at full throttle , can cause excessively high temperature in the transmission . These temperatures may tend to overheat the engine cooling system as well as cause possible damage to the transmission. If excessive temperature is indicated by the engine coolant temperature gauge, stop the vehicle and determine the cause. If the cooling system appears to be functioning properly, the transmission is probably overheated. Shift to N and accelerate the engine to 1,200 to 1,500 RPM . This should reduce the oil sump temperature to operating level within a short time. If high temperatures persist , stop the engine and have the overheating condition investigated by service personnel.

Caution Do not operate the engine for more than 30 seconds at full throttle with the transmission in gear and the unit stationary. Prolonged operation of this type will cause the transmission oil temperature to become excessively high and may result in severe overheat damage to transmission components . Do not leave transmission in drive for more than 5 minutes while stationary because of heat damage. If the transmission overheats during normal operation , check transmission oil level.

General Information - Detroit Diesel Engines

Caution Cooling fan is driven by hydraulic pressure. Flow is controlled electrically by a thermostat which senses engine coolant temperature. Any time the engine is running the fan may engage and start without warning. Also, on hydraulically driven fans, the fan may start and run for several seconds when the engine is shut off or if electrical power is interrupted. Shut off engine and wait for fan to stop before servicing. When inspecting or servicing engine or other components in engine compartment the engine control switch must be placed in OFF or REAR position to prevent starting of the engine from the driver's area.

Check crankcase oil level before starting and when refueling. Always check oil level with engine stopped . The dipstick has 2 markings , FULL and LOW , and the distance between them represents 4 quarts (3.8 litre) for the 6V92 and 6 quarts (5.75 litre) for the 8V92 engine . Refer to table 8-2 for recommended oil. • Check (with engine stopped) drive belts for cracks, breaks and frayed edges. While checking belts, look for oil, water or fuel leaks. • Check (with engine stopped) for water in the fuel. Drain a cupful of fuel from the bottom of the tank to remove water or sediment. Fill fuel tanks after completing a run. Partially-filled tanks will collect moisture if the coach is allowed to sit for an appreciable length of time. Use number 2-D diesel fuel (with a minimum Cetane number of 40). Keep fuel clean . Inspect Racor filter bowl periodically and observe WATER-IN-FUEL indications on the dash gauge. Remove and clean filter bowl as necessary . Number 1-0 diesel fuel may be used in cold temperatures or when operating in altitudes above 5,000feet. • Check coolant level (with engine cool and off). Fill to the proper level with water and permanent-type anti-freeze. Use clean water that is low in scale forming minerals, not softened water. Leave space for expansion. (Note that Nalcool 2000 is compatible only with ethylene-glycol base coolants.)

Racor Fuel Filter

A Racor fuel filter is incorporated in the diesel fuel supply line and processes the fuel supply for maximum purity . The fuel filter also includes a built-in preheater, which operates from the 12-volt battery supply and a water sensor, which lights a dash indicator when the water level in the filter bowl is high enough to require drainage.

Fuel Line Heater

A thermostatically controlled fuel line heater is located between the tank and the engine.

Leveling Jacks

The motorhome is optionally equipped with, four heavy-duty leveling jacks; one at each corner of the chassis. Because the rear leveling jacks must extend or retract a greater distance than the front jacks, their operating cycle takes appreciably longer. Overall system operation is controlled and monitored at the leveling jack controls, while each jack is independently operated by one of four respective EXTEND-RETRACT levers located on the floor to the left of the driver, figure 2-20. A dash indicator and a buzzer (when ignition switch is on) provide visual and audible signals to show that the associated leveling jacks are not stowed to a safe travel position.

Caution Severe injury or death may result. DO NOT use the leveling system for changing tires or working under the vehicle. Keep the rear wheels in firm contact with the ground with the parking brake set. With the leveling jacks extended, there is a possibility the vehicle may move either toward the front or the rear.

Operating the leveling jacks

Note 12 Volt master switch must be on to operate leveling jacks.

- Set LEVEL MASTER switch (see figure 2-20) to ON position. Note that the LEVEL WARNING indicator will light. LEVEL SYSTEM indicators LF RF. LR and RR are lit only when the respective corner of the coach is low.

- De-pressurize the tag axle by setting TAG DUMP switch to DUMP : de-pressurize front and rear axle by setting associated SUSP. DUMP switch to DUMP. Caution Always dump tag axle air pressure before the front and rear suspension and pressurize it after the front and rear suspension to avoid damage to tag axle suspension

- Lower the front leveling jacks by setting the LF and RF floor controls to EXTEND position . As soon as the jacks contact the ground , as indicated by the characteristic landing gear thump , release the respective control lever to prevent further jack movement.

- Operate the EXTEND-RETRACT levers for 'the rear leveling jacks (LR and RR) as necessary to level the rear end of the coach. The blue LR and RR LEVEL SYSTEM indicators will extinguish when the respective corners are leveled .

- Operate the EXTEND-RETRACT levers for the front leveling jacks (LF and RR) as necessary to level the front of the coach.

- To re-stow the leveling jacks prior to moving the coach , start engine to initiate air compressor operation , re-pressurize the air suspension system for the front, rear and tag axle by setting the associated DUMP switches to the FILL (up) position, in the following sequence. First pressurize front and rear axle suspensions by setting the associated DUMP switch to FILL position; then pressurize tag axle by setting the TAG DUMP switch to FILL position. Check that AIR PRESSURE REAR and AIR PRESSURE FRONT gauges each read between 100 psi and 120 psi; check that TAG AXLE PRESSURE gauge reads 50 psi.

- When the air suspension is once again stabilized, pull all four leveling jacks controls back to the RETRACT (locked) position. The red warning indicator will extinguish when the jacks are in the stowed position. Note If the jacks are not withdrawn before driving away, the buzzer will sound. Caution Do not drive the coach unless the tag axle is correctly pressurized to assure even weight distribution. There must be pressure in Tag Axle air bags to prevent flat spotting of Tag Axle tires during brake application.

- Set LEVEL MASTER switch to OFF position. This completes one full operating cycle tor the leveling jacks system.

Living Area Facilities (Interior & Exterior)

This section provides information on operation of the appliances and systems which contribute to the comfortable living conditions within your motorhome.

Sofa

Your Wanderlodge sofa converts into a double bed sleeper. The sofa converts in much the same way as a sofa bed in your home. Pull up and out on the seat until the sofa is fully extended and the back of the sofa is lying in the flat position. To fold the sofa back up into the sitting position pull up on the sofa seat and at the same time push in on the sofa seat until the sofa is locked into the sitting position .

Dinette Area

The dinette area , figure 3-1 includes the area thermostat , Gas/Smoke Alarm , Systems Monitor Panel and four place bench type dinette which converts into a 3/4 size bed. To convert dinette into bed you must first lift up and remove the back cushions from both sides of table, lay these cushions to the side. Next unsnap and slide the bottom cushions toward the back rests. While holding table up reach underneath the table to unlock and fold leg under table. Raise end of table up to remove table top from wall brackets and lay table top into place on dinette base. Place back cushions in open space on lowered table top and dinette base . To convert back to dinette just reverse order of steps above .

Galley Facilities

The galley, figure 3-2 , includes a double sink , food center , refrigerator /freezer , two burner gas cooktops and micro/convection oven. The refrigerator operates from the LP gas supply, from the 120 volts ac supply, or from 12 volt alternator output while in transit. The cooktop also operates from the LP gas supply , Operating procedures for these appliances , given in the following paragraphs assume that the main LPG valve is on. An LPG leak detector, located under the rear dinette seat continuously monitors the area for LPG leakage , shutting off the LPG supply and sounding an alarm if leaks are detected.

Refrigerator

Understanding just how the refrigeration process operates will help to explain one of the important reasons why it is necessary to level a parked motorhome. The gas-fired (or electrically-heated) boiler converts the ammonia -water solution to distilled ammonia vapor, which is carried to the finned condenser, where it liquifies. The liquid flows to the evaporator , where it creates a cooling effect by evaporating into a circulating flow of hydrogen gas. If the evaporator coil is not level, the liquid accumulates, form ing pockets which do not readily evaporate and impair or block gas circulation, inhibiting the coo ling process. When the coach is parked, it must be leveled to assure comfortable living accommodations . The refrigerator will then also perform well. Place a bubble level (furnished with unit) on the freezer shelf. When the vehicle is moving , the continuo us rolling and pitching movement will not affect the refrigerator as long as the movement passes either side of level; but when the coach is parked, the refrigerator must be level (within 6 degrees).

Operation: Before starting the refrigerator , check the gas valve in the piping. Do not forget the valve on the rear of the refrigerator.

- To start the refrigerator set switch 7 to position On. Light 10 shall now be green.

- Turn the thermostat knob inside the cabinet to suitable setting, e.g. start with normal position.

- To shut off the refrigerator set the switch 7 to position Off.

General Information on the Operation of the Refrigerator This refrigerator is equipped with an Automatic Energy Selector (AES) system. The control system selects the most suitable available energy source. The selection will be made with highest priority to 120 V AC , second priority is to 12 V DC from the alternator , and lowest priority has gas operation . No manual operation is necessary for change of energy source unless desired . The automatic energy control will, when switched on, start up in AES mode. The AES mode follows the above mentioned priority list and will select the best energy source available.

Note The refrigerator also has a built in Battery Protection System.

With this feature, battery voltage will not be allowed to energize the 12V. heater coil until there is 13.6 volt at the + terminal of the refrigerator. This means that not only must the ignition switch be on but the alternator must be providing charging voltage to the batteries. This was designed to prevent burnout of a marginally rated alternator with consequent battery discharge and premature travel termination (highway breakdown). If, after starting, there is so much of a coach load that the alternator can't put out 13.6V. then the refrigerator will not go into the 12V. mode but run on L.P.G. only.

If the coach was previously plugged into shore power and had the L.P.G. shut off (either at the refrigerator or main valve) then the unit would not operate while in transit. There must be LPG available for refrigeration assurance. Lamp 1LR will come on if there is no gas light up. Whenever this light comes on there is no refrigeration as LPG is the lowest priority.

When the alternator provides voltage in excess of 13.6, the unit will ope rate satisfactorily with the 12V. heater. If, however , because of some additional load during travel , the voltage should drop below 11.6, then unit will switch to LPG. See Refrigerator Owner 's Manual for complete operating and care instruct ions.

Gas Cooktop

The gas supply for the cooktop burners is provided from the LPG tank. Make sure that the main valve (on tank ) is turned On before use. The cooktop is equipped with an electric igniter instead of pilot light.

Lighting Cooktop Burner

- Depress knob and turn counter clockwise to HI position . Note - A faint popping noise will be heard during step 1.

- After burner has lit, turn knob a few degrees clockwise until popping stops.

- Turn knob to desired setting.

Microwave/Convection Oven

The microwave/convection oven provides programmed microwave cooking , convection operation for crisp, even browning, or a combination of both. Caution Notes

- Unlike microwave-only ovens, all microwave/ convection ovens have a tendency to become hot on the cabinet and oven door, as do conventional range ovens and convection-only ovens. Be careful when touching parts other than the handle or control panel during or immediately following cooking that uses convection heat.

- Do not cook eggs in the shell. Steam builds up inside the shell and it may explode from pressure. Shelled hard-cooked eggs should be sliced or cut up before reheating in the microwave oven. You may hard-poach eggs for salads and casseroles.

- Pop popcorn only in special microwave poppers, following manufacturer's directions. Do · not use oil unless specified by the manufacturer, or heat longer than recommended. Never pop popcorn in paper bags or glass utensils.

- Do not heat oil or fat for deep-frying. the temperature of the oil cannot be controlled and it may overheat.

- Do not attempt to can in the microwave oven as it requires prolonged high temperatures .

- Do not operate the oven empty.

- Remove wire twist-ties from bags before placing in oven.

This oven uses a microprocessor, the electronic brain that provides a wide variety of cooking programs which could not be achieved by conventional control methods. The operation of the oven is controlled by touching the appropriate pads arranged on the surface of the control panel, figure 3-5. The lighted digital readout will display the cooking time, convection temperature , sensor or compu-cook setting, or time of day, and indicators show the variable cooking setting or cooking function you have programmed. See owners manual for operating instructions.

CORIAN Counter Tops

Even stubborn stains - such as grape or beet juices - wipe off with a damp cloth and household cleanser . Because CORIAN is solid all the way through , it cannot be harmed by abrasive cleansers and normal household cleaners.

CORIAN is strong and tough , but slicing on it with knives can cause scratches. Use a cutting board.

While CORIAN does provide an extra measure of protection (better than ordinary countertops), it is not recommended as a hot pad. Do not place hot pots and pans directly on your CORIAN countertop .

Since it's a solid material with color and pattern all the way through, unusual damage such as cigarette burns , scratches , or other surface abuse can usually be removed using ordinary household cleansers or fine sandpaper. If the stain persists, or if the scratch is particularly deep, first use a medium sandpaper (120 or 240 grit) then fine sandpaper (320 or 400 grit) followed by circular motion buffing with a scotch Brite pad to match the gloss of adjacent surfaces. Household cleanser , steel wool or DuPont No. 7 polishing compound can also be used if higher gloss levels are needed.

Caution: Certain chemicals found in the home - such as paint removers, paint brush cleaners, acid drain cleaners and certain brands of nail polish and polish removers - can harm CORIAN if left in contact even for short periods of time. These materials should be wiped away promptly and flushed with water. Depending on time of exposure, surface damage caused by these materials can sometimes extend too deeply for practical repairs.

Food Center

A built-in variable-speed motor-driven unit , figure 3-6, may be used with blending attachments for a large variety of food preparation tasks . The food center is designed for ac operation and is operable only when the generator is on ; or when coach systems are connected to an external shoreline hookup.

Bathroom

Water Pump Switch Two Water Pump On-Off switch/indicators are provided for separate control of water pump operation. One switch is located on the control panel In the galley area ; the second is located in the bathroom. The pump may be operated On or Off from either location. The associated indicator is lit whenever power is being supplied to the pump. Setting either switch On pressurizes the water system, with the pump operating on demand to maintain constant pressure . Continuous or erratic pump operation can indicate an empty water tank, system leakage , or air lock in hot or cold water lines. (Air locks are normally caused by movement of water in the tanks during pump operation.) Since tank water level and water pressure can vary with road movement , leave water pump switch Off while the coach is moving. The water pump and air accumulator are located in the bed base cabinet.

Tub Unit

The tub unit includes a pressure-balancing single mixing valve, tub water spout with shower wand diverter button , shower head and drain lever.

Toilet

The toilet , figure 3-7, operates from the fresh water supply , flushing wastes directly into the sewage holding tank. The double-flush foot pedal located at the bottom of the bowl controls the amount of water delivered into the bowl and opens the sliding valve to the tank. After use, depress bowl drain pedal until water swirls , draining wastes into tank, then release pedal. A water-save r feature, consisting of a manually-operated spray hose, is located inside cabinet at side of bowl. To raise the level of water in the bowl, press on the small foot pedal. A water shut off valve is located in supply line to toilet and used to stop water flow to toilet.

Vent and Exhaust Fans

Fans are located in the galley and bathroom. These fans have controls built into the housing. The lid must be raised to desired position before fan is turned on. The fans can be used as exhaust fans by pressing the OUT side of rocker switch or as a vent fan by pressing the IN side of rocker switch.

Heating Systems

Three types of comfort heating systems are used in your motorhome: gas/hot air heat; electric heat; and engine hot water circulating heaters. Two gas/hot air furnaces are used in the coach. Each unit has a separate zone thermostat, figure 3-9. One furnace is located in the living room, another is in the bathroom area. The bathroom furnace is also used to supply hot air to the bedroom via a separate duct.

Separate heating can also be provided by circulating hot-water heaters (chassis heaters) when the engine is operating and the Winter-Summer Heat Selector switch (located on the pilot's area overhead dash) is in Winter position. These heaters share the area thermostat with the LPG furnace.

Four electric convection heaters (120 volt) are located in the bedroom , bathroom , galley area, and living area. On-Off thermostat switches are located on each heater. Three freeze-protection heaters (120 volt) are used to protect plumbing and water supply tanks.

Gas/Hot Air Furnace

To operate the furnace, proceed as follows:

- Turn manual gas valve (at furnace front) to Off position.

- Set thermostat above room temperature. A 1 O seconds delay will occur before the blower starts.

- Allow blower to run for five (5) minutes for combustion chamber purge cycle.

- After five (5) minutes , set thermostat to the OFF position.

- Turn manual gas valve to ON.

- Set thermostat on desired temperature.

- Allow 24 seconds for ignition to occur.

- If burner does not light, set thermostat on OFF and repeat steps 1 through 7.

- If after three (3) attempts with no ignition , go to shutdown and contact a qualified service agency. Do not continue to cycle furnace through thermostat in an attempt to get ignition.

When coach temperature drops below the thermostat setting, the internal relay contacts close to operate the blower. The air flow created by the blower closes an air-actuated switch that, in turn, energizes the main burner gas line solenoid valve which then lights from the electronic ignition.

Caution Do not store items in or near the burner compartment.

When the coach temperature exceeds the thermostat setting , the relay contacts open. This shuts off the burner gas supply but the blower continues to operate until residual heat within the furnace is dissipated , when a thermostatically-controlled relay turns off the blower. Air for the sealed combustion chamber is pulled in from outside the coach, routed around the heat exchanger , then exhausted through the outside vent. Recirculated fan-forced air blowing across the heat exchanger is used to heat the coach interior.

Switch at bottom of thermostat must be Off (to left) if operation of furnace at lower temperatures is not desired.

Hot-Water Heating Systems

Five sources of hot water heating are provided which depend on heat generated from engine operation. One heater (90,000 BTU), which serves the pilot's and co-pilot's area, is controlled by-the Front Heat switch on the dash ; and three chassis heaters , (50,000 BTU) under the dinette seat, livingroom sofa and in the bedroom rear storage area, are controlled by the thermostat in that area. The bathroom chassis heater (15,000 BTU) is controlled by the bathroom thermostat.

The engine coolant is normally routed through the engine cooling system and the water heater, which also can be heated electrically, to provide the hot water supply for the coach. However, by operating the Winter-Summer Heat Selector switch , the engine coolant can also be diverted through the previously-mentioned area heaters, via a solenoid valve. The coolant level in the engine radiator should be checked after these valves are opened. Note that two pumps are used to circulate hot water through the coolant lines. One pump is controlled by the Aux. Pump switch (located on the pilot's overhead dash), the second pump is turned on automatically whenever the Front Heat switch is on.

Chassis heater blower motors (dinette seat, front sofa and bedroom rear storage area), are controlled by On-Off Heat switches adjacent to the heater louvers as well as the area thermostats . HILO blower speed switches are also provided. The front heater is equipped with three squirrel-cage dual-speed blowers, operated from separate dash controls. One blower provides defroster air; one provides air to the pilot's side; the third provides air to the co-pilot's side. Use Defrost Hi-Off-Low switch for setting the defroster blower speed; use the left and right Hi-Off-Low Heat switches to control air flow to the pilot's and co-pilot's sides, respectively. To supply heat, the dash Front Heat switch must be On.

Note If additional defrosting action is needed, turn auto air conditioning temperature control to the warmest position and turn auto air conditioning fans to high speed. This will circulate additional hot air about the windshield area.

Engine heat is picked up by the engine coolant which is pumped through the heaters inside the coach and back into" the engine. A typical heater consists of a heat exchanger, or core, and a fan which moves the air across the core, transferring heat from the engine coolant into the room.

Heating System Operation

Satisfactory performance of the hot-water circulating type of heating system depends on the following conditions:

- Engine Coolant Temperature - Coolant temperatures vary between 180 and 195 degrees F, during normal engine operation.

- Coolant Flow - Coolant flow varies with the engine speed. Setting the Aux. Pump switch (located on the pilot's overhead dash) to On turns on the auxiliary pump (located in the engine compartment) to increase the coolant flow through the system. This feature may also be used to reduce engine overheating during normal driving conditions .

- Proper Fan Operation - All fan motors are two speed and can easily be checked for proper operation by listening to tli e motor speed change as the switch is operated.

More heat will be generated by the engine when it is also used to move the coach. Be sure that the engine radiator is full and that all coolant flow valves are open. Warm engine to operating temperature and set heating system switches as follows:

- Winter-Summer Heat Selector to Winter positon

- Aux. Pump to On

- Front Heat switch to On

- Left and right Heat blower switches to Hi or Low

- Thermostats to desired temperature.

Electric Heaters

Electric forced-air heaters (120 volts) are located in the bedroom, bath, galley and living room areas. Each heater is controlled by a combination On-Off switch /thermostat. Heater operating voltage is provided from the same switches which control the air conditioners. Air conditioner On-Off toggle switches , on the TV control panel above the pilot , must be in On position and individual A/C switches Off.

Freeze Protection Heaters and Heat Tape

Freeze protection heaters (120 volts) are thermostatically-operated to turn on and protect the water supply tanks and associated plumbing in the event that temperatures drop below 40°. Two heaters are used ; under the kitchen sink; and within the bed base cabinet. Thermostatically controlled heat tape (120 volts) are run on the copper water tubing and then wrapped with insulation . Heat tapes start to heat at 36°F and stop at 43°F.

Note This freeze protection will greatly decrease the chances of frozen water lines provided the coach is plugged into outside power (one SOA. or two 30A. power cords) or the generator is run continuously during cold weather periods.

Air Conditioners

Three 13,500 BTU roof air conditioners located in the living room and bedroom. The 12 volt master ON/OFF switches are located on the pilot's left overhead control panel. Fan and thermostat controls are located on the roof air conditioners. Each air conditioner is equipped with a 1,000 watt heat strip.

Systems Monitoring and Control Panel

The systems monitoring and control panel, figure 3-11 , is located on the rear dinette wall. This one panel provides a convenient means of displaying inside and outside temperature, time , level of potable water supply , holding tanks, and LPG supply, as well as other monitoring and alarm functions discussed in the following paragraphs.

The systems monitoring and control panel, figure 3-11 , is located on the rear dinette wall. This one panel provides a convenient means of displaying inside and outside temperature, time , level of potable water supply , holding tanks, and LPG supply, as well as other monitoring and alarm functions discussed in the following paragraphs.

Water Pump - The water pump switch is one of two switches that can be used to turn the water pump on or off. The ON indicator will be lit when power is being supplied to the pump.

Refrigerator Alarm - When the switch is on the refrigerator temperature is being monitored. Normally , the ON indicator is lit; if the refrigerator temperature increases to an unsafe level , the WARM indicator lights with an accompanying audible alarm.

Gas/Smoke Alarm - The gas /smoke alarm is a gas leak detector designed to sense dangerous concentrations of LP gas or carbon monoxide within the coach. There are four (4) sensors mounted at floor level (LP gas is heavier than air) for the three furnaces and the refrigerator . One sensor is located above the 120 volt ac distribution panel (Load center) to monitor carbon monoxide. Carbon monoxide , of course, is the most deadly of the products of combustion. It will provide an alert in the event of a short circuit at the load center. The alarm has been factory-calibrated to an alarm point of 2,000 PPM propane for standard conditions (temperature, 20 degrees C + I - 2 degrees ; relative humidity 65% + /- 5%. This provides for a minimum of false alarms consistent with providing reasonable safety .

To turn on the unit, set On-Off switch to On and observe that Power On indicator is lit. Excessive propane PPM conditions are indicated by the sounding of the audible alarm and lighting of an indicator associated with the danger area. The alarm, if left turned off for a period of time, has a warmup period of about one minute. During this time , the alarm may sound. This is a normal response and should stop once the unit is warm.

Clock/Thermometer - The clock/thermometer provides , on demand , a digital display of inside and outside temperature, digital time display , and an alarm function . Operate the panel controls as follows:

- Monitor inside or outside temperature (°F) by pressing the Temp In or Temp Out buttons. There is an internal adjustment , at the rear of the unit, which may be used to calibrate the temperature readings. (Calibration of this unit is described in Section VIII.)

- Set the clock by depressing the Fast or Slow Set button until the correct time is shown. PM is indicated by lighted dot in the upper left corner. The dot in the center of the display marks the seconds.

- Set alarm as follows : depress Alarm Display button then depress the Fast or Slow button to set the alarm time. Dot in upper left corner will light when alarm is set for PM. After setting the alarm , release Alarm Display button to return to the normal time mode. To activate the alarm feature , depress Alarm On/Off button to On; to shut off the alarm, depress Alarm On/Off button and release so it pops out to Off. Note When 12 V. power has been interrupted (batteries disconnected or Electronic Master switch turned off) clock display will flash "12:00". Reset clock to eliminate flashing. Alarm will also have to be reset.

Tank Monitor - The Tank Monitor panel provides an illuminated readout of the content level of the pure water , gray and waste water tanks, and the LPG tank level. When full, each of these tanks has the following capacity: pure water supply , 116 gallons (See Table 8-4); gray water holding tank, 100 gallons ; body waste tank, 100 gallons; and LPG tank , 43.5 gallons (148 lb.). Use the features of this panel as follows:

- Monitor Pure, Gray or Waste Tank levels by depressing the respective button. The content level remaining in the tank is indicated by five sets of lit readings . The E lamp, at the left of the display, is lit all the time ; if the next indicator is lit, the level is approximately 1 /4 tank; if the center indicator is lit, tank level is between 1 /2 and 3/4 full ; if the 3/4 indicator is lit, tank level is between 3/4 and full; and if the F indicator is lit, tank level is full. If only the E indicator is lit, the tank level is between empty and 1 /4.

- LPG tank level can be monitored in the same manner as the water tank level by depressing the Propane Tank button. Note that this display is pre-calibrated. However, if it is necessary to recalibrate the display, this can be done when the tank is full by setting a rear-panel adjustment. Note that the display will read Full when the LPG tank float reads 80% because the remaining 20% volume is needed for expansion.

Waste Odor Control Panel - This panel controls the cycling and electrolysis action of two pairs of stainless steel electrodes contained within the body waste holding tank. A 12-volt current is passed between each pair of electrodes for a 16- minute On period (green LED); and switched off for a 48-minute Off period (red LED). For each cycle, the current is reversed so that the electrolytic action does not excessively erode the steel electrodes.

As current flows through the waste liquid, it oxidizes the organics and eliminates associated odor. To increase odor control effectiveness , a tablespoonful or two of salt may be added through the toilet if desired.

The electrodes (probes) are replaceable.

Generator Switch - The generator Start-Stop switch provides the same features as the generator switch located above the driver. Press switch to Start position and hold until generator starts as shown by the switch indicator light. Press switch to Stop to shut-down the generator (light extinguished) . Press switch to Stop (and hold for pre heat).

LP Gas Leakage Detector