Difference between revisions of "Dupree Twis-Loc Manual Valve"

| Line 1: | Line 1: | ||

[https://dupreeproducts.com Link to manufacture's page][[File:Dupree Twis-Loc Valve .png|thumb|500x500px|Dupree Twis-Loc Valve]] | [https://dupreeproducts.com Link to manufacture's page][[File:Dupree Twis-Loc Valve .png|thumb|500x500px|Dupree Twis-Loc Valve]] | ||

| − | The Dupree Twis-Loc valve was originally developed and marketed as the Owens Valve in 1964, and it has been in production ever since. The Twis-Loc Valve has been installed by many manufacturers during this time such as, Airstream, SilverStreak, Bluebird, Newell and numerous other bus and recreational vehicle manufactures. The Twis-Loc's significant feature is its certainty of operation and valve position with all parts being easily replaceable. | + | ==Twis-Loc Overview & History== |

| + | The Dupree Twis-Loc valve was originally developed and marketed as the Owens Valve in 1964, and it has been in production ever since. The Twis-Loc Valve has been installed by many manufacturers during this time such as, Airstream, SilverStreak, Bluebird, Newell and numerous other bus and recreational vehicle manufactures. The Twis-Loc's significant feature is its certainty of operation and valve position with all parts being easily replaceable. | ||

| − | |||

| − | |||

| − | |||

The heart of the Dupree termination system is the Twis-Loc gate valve; one of the most important components in your system. The Twis-Loc's features certainty of operation and the valve position while being unsurpassed in serviceability. | The heart of the Dupree termination system is the Twis-Loc gate valve; one of the most important components in your system. The Twis-Loc's features certainty of operation and the valve position while being unsurpassed in serviceability. | ||

| − | |||

| − | |||

==Operation== | ==Operation== | ||

| Line 18: | Line 14: | ||

To close the valve, align the handle. perpendicularly to the body of the valve. Push the handle against the body of the valve, giving it a 1/4 turn clockwise. When the handle will turn no further, it is aligned with the valve body and the valve is closed. As you turned the handle, slots in the handle rode up the guides in the body. The slots were stopped at the top of the guides when the valve reached the closed position. The spring in the handle tightened the valve closed, and now keeps the handle in place until you choose to move it. | To close the valve, align the handle. perpendicularly to the body of the valve. Push the handle against the body of the valve, giving it a 1/4 turn clockwise. When the handle will turn no further, it is aligned with the valve body and the valve is closed. As you turned the handle, slots in the handle rode up the guides in the body. The slots were stopped at the top of the guides when the valve reached the closed position. The spring in the handle tightened the valve closed, and now keeps the handle in place until you choose to move it. | ||

| − | == Maintenance == | + | ==Maintenance== |

Insert maintenance procedure here | Insert maintenance procedure here | ||

| − | === Gate Lubrication Procedure === | + | ===Gate Lubrication Procedure=== |

| − | === Gate Replacement Procedure === | + | ===Gate Replacement Procedure=== |

<br /> | <br /> | ||

==Parts List== | ==Parts List== | ||

Revision as of 20:06, 6 April 2021

Twis-Loc Overview & History

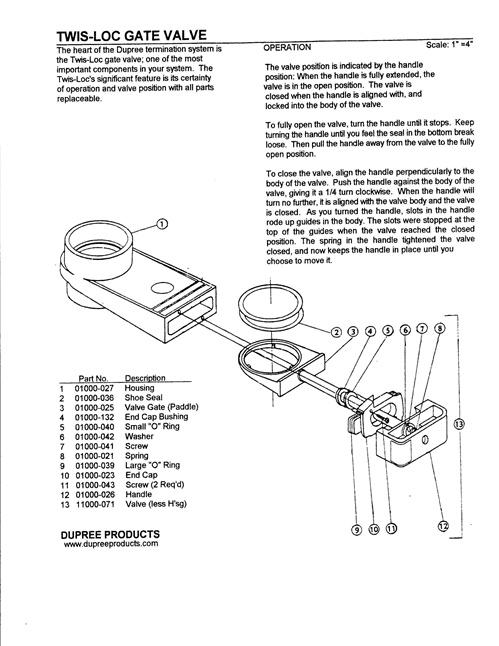

The Dupree Twis-Loc valve was originally developed and marketed as the Owens Valve in 1964, and it has been in production ever since. The Twis-Loc Valve has been installed by many manufacturers during this time such as, Airstream, SilverStreak, Bluebird, Newell and numerous other bus and recreational vehicle manufactures. The Twis-Loc's significant feature is its certainty of operation and valve position with all parts being easily replaceable.

The heart of the Dupree termination system is the Twis-Loc gate valve; one of the most important components in your system. The Twis-Loc's features certainty of operation and the valve position while being unsurpassed in serviceability.

Operation

The valve position is indicated by the handle position; When the handle is fully extended the valve is in the open position. The valve is closed when the handle is aligned with, and locked into the body of the valve.

To fully open the valve, turn the handle until it stops. Keep turning the handle until you feel the seal in the bottom break loose. Then pull the handle away from the valve to the fully open position.

To close the valve, align the handle. perpendicularly to the body of the valve. Push the handle against the body of the valve, giving it a 1/4 turn clockwise. When the handle will turn no further, it is aligned with the valve body and the valve is closed. As you turned the handle, slots in the handle rode up the guides in the body. The slots were stopped at the top of the guides when the valve reached the closed position. The spring in the handle tightened the valve closed, and now keeps the handle in place until you choose to move it.

Maintenance

Insert maintenance procedure here

Gate Lubrication Procedure

Gate Replacement Procedure

Parts List

- 01000-027 - Valve Housing

- 01000-036 - Shoe Seal

- 01000-025 - Valve Gate (aka Paddle)

- 01000-132 - End Cap Bushing

- 01000-040 - Small O Ring

- 01000-042 - Washer

- 01000-041 - Screw

- 01000-021 - Spring

- 01000-039 - Large O Ring

- 01000-023 - End Cap

- 01000-042 - Screw (x2 required)

- 01000-026 - Handle

- 11000-071 - Gate Assembly (less housing)